Employment

Let’s Make North Carolina a Workplace Leading State

Nichola Lowe, Professor, UNC-Chapel Hill Department of City and Regional Planning

February 9, 2022

Walter Vicente, Plant Manager at one of Carolina Textile District's supported co-ops, Opportunity Threads, a completely sustainable worker-owned cut and sew factory. (Photo Credit: Opportunity Threads)

Manufacturers throughout North Carolina are responding to COVID-19 pandemic needs by making better and more useful products. As the nation’s fifth-ranked manufacturing state, North Carolina has the capacity to expand supply chains, retool factories, and harness our innovation ecosystem to produce essential, life-changing, and planet-saving products and technologies—now and well into the future. But this pandemic economy is also a defining moment for North Carolina to step up as a national leader in the promotion of high-quality manufacturing jobs—not just by tapping our existing strengths in workforce development to prepare more individuals to move into rewarding manufacturing careers, but pushing that system even further to prepare manufacturing workplaces to attract, retain and nurture current and future talent.

Workplace Actions

Workplace improvements target the job itself, striving to upgrade job quality by identifying and resolving problematic organizational, inter-personnel, or institutional dynamics and practices. Actions in this vein are rooted in an understanding that low-quality jobs—rather than unprepared applicants—are the greatest drag on the regional economy and thus need to be improved through coordinated institutional action. Workplace actions also seek to end racial inequities, freeing workers of color from dead-end, unsafe or demeaning jobs, while also taking steps to narrow the racial wage gap.

Jobs that pay too little or fail to provide support for upward mobility and racial inclusion drive good employees away, thus depriving manufacturers of much-needed creativity and ingenuity. The risk for business is clearly visible today in what economists are calling the Great Resignation of 2021, with workers rejecting poor quality job offers, further intensifying pre-pandemic worker shortages.

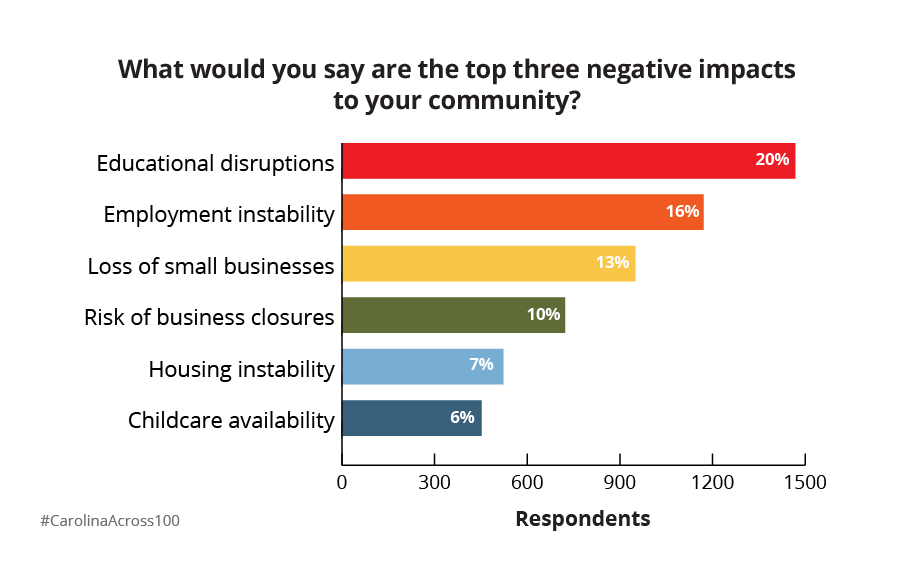

Data from the recent Carolina Across 100 listening survey underscores this concern. Employment instability and workforce/staffing-related issues were among the top negative impacts of COVID-19 identified by the respondents. One of those individuals expanded on this saying, “Every business I enter is looking for employees. Often these jobs do not pay enough to live on, but I never knew there to be so many vacancies prior to the pandemic.”

Some manufacturers are prepared to address this challenge head-on, raising wages and introducing other work-enhancing changes in order to attract and retain workers and diversify their workforce. But many other manufacturers in this state are not there yet and will need additional support to move in that direction.

Connecting Institutional Dots

Fortunately, North Carolina has the institutional seeds within its robust workforce and economic development networks to launch a far-reaching workplace development response. Community colleges in our state are experimenting with more dynamic forms of employer engagement that go beyond standard curriculum development advisory roles for local manufacturers, allowing the colleges to also shape industry hiring and career development processes. Some colleges can extend their influence further, helping manufacturing firms in their region formalize systems of work-based mentoring and learning, while also illuminating career pathways inclusive of frontline manufacturing workers. Economic developers, for their part, are leveraging strong state support for manufacturing recruitment and retention, with pioneering practitioners linking incentive offers to living-wage standards and local hiring goals, thus helping to forge connections to communities of color with deep, yet often undervalued talent pools. Additionally, North Carolina hosts the nation’s oldest manufacturing extension system, which has served thousands of smaller-sized manufacturers over the course of several decades, helping those firms access more profitable markets by concurrently embracing advanced technology and more encompassing talent management.

Inspiring examples exist across North Carolinian communities as well, showing others how to connect these institutional dots. The Carolina Textile District in rural Morganton supports hundreds of apparel and textile firms in our state, not only facilitating a connection to a new generation of product designers and entrepreneurs but creating collaborative, place-connecting production and sourcing networks that are centered on shared goals of livable wages and environmentally friendly production. Apprenticeship 2000, based in Charlotte, is another enduring partnership, this one involving a half-dozen advanced manufacturing firms, the Central Piedmont Community College, and Charlotte’s public school system. Their successful collaboration—which has been celebrated nationally—has inspired other communities in North Carolina to launch their own cohort-based apprenticeship programs, grouping together local manufacturers to create both the scale and flexibility for nurturing next-generation manufacturing talent.

Workers from Opportunity Threads, a sustainable worker-owned cut and sew factory. (Photo Credit: Opportunity Threads)

Employing more people in North Carolina’s manufacturing sector is certainly a good thing—but turning manufacturers into “employers of choice” is even better for our state. Let’s use the historic moment created by this pandemic to elevate and expand what we know works well, ensuring North Carolina’s manufacturing future is inclusive and broadly prosperous for businesses and workers alike.

UNC-Chapel Hill’s Carolina Across 100 initiative is a 5-year program charged by Chancellor Kevin Guskiewicz which will partner with communities in all 100 North Carolina Counties to aid in pandemic recovery and help build resiliency. Stay connected with Carolina Across 100 as we continue to share data and resources.